Basic Microscopy Concepts - Incident Light Microscopy for opaque samples

Posted by Motic America on

A closer look on Incident Light Microscopy reveals a new and noticeable fact. In a compound microscope for opaque samples, the objective plays two roles. First, like in a Transmitted light setup the objective is part of the imaging process. Quality and performance of the objective are essential elements to get reliable and “close-to-truth” results.

Secondly, the objective additionally is part of the illumination system. Light from the lamp house passes the illumination axis and is deflected by a 45° orientated semi-transparent mirror. Sent through the objective, the light is reflected by the sample surface and brings back sample information to the eyepieces/camera. For a beginner it is difficult to accept that both illumination and imaging processes do not interfere visually.

Similar to Transmitted light microscopy with its Koehler illumination setup based on field diaphragm and condenser diaphragm, the illumination axis of an industrial microscope carries both options for adjusting the illumination in reference to the sample.

The Field diaphragm defines the illuminated area, the aperture diaphragm regulates contrast as well as depth of field. In case of a flat polished sample surface, depth of field of course is negligible.

The semi-transparent mirror in the front part of any Epi-illuminator is a funny thing. It deflects the light by 45°, at the same time being transparent by 50%. In a Fluorescence setup, a dichroic mirror separates different colors by wave length quality, here we talk about a 50/50 quantitative separation of white light.

Epi-illumination in a compound microscope can be verified in 2 different hardware setups. The Inverted microscope is a more expensive and complex construction but has got obvious advantages. First, we need only one flat surface on the sample to start the investigation. Secondly, we do enjoy the freedom of an enlarged sample size. As in an Inverted metallurgical microscope mostly the focus mechanism is done by moving the nosepiece with its objectives, samples with reduced weight limitations can be handled.

For upright microscopes, we need 2 flat surfaces orientated parallel for the positioning of the sample.

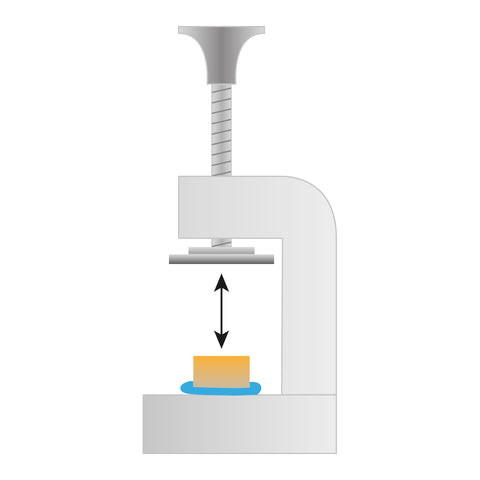

A mechanical press together with some modeling clay from a toy shop are helpful tools to make a metallurgical sample ready for investigation. A metal slide is the carrier, and the flexible modeling clay with the sample placed on top can be pressed to position the sample properly.

Opaque samples are treated with incident light. Take care of the correct selection of objectives without cover glass correction. The objective sleeve indicates this feature as a “0” (in the following case behind ∞, referring to the optical concept):

A suitable combination of optics and sample preparation/positioning produces significant results in quality control cases of automotive industries, but also in technical education environments of universities.

Want to know which microscopes fit you best? Fill in the form below and our specialists are glad to help!